1. Title

Food Traceability and Risk Prediction Platform Using Apache Spark

and Neo4j

2.

Introduction

This project aims to develop a

traceability platform for the Food supply chain using advanced analytics and

machine learning models. By leveraging Apache Spark for data processing and

Neo4j for representing supply chain entities in a graph structure, the platform

will enhance traceability, improve supply chain transparency, and provide

predictive analytics to manage quality and minimize risks, such as spoilage and

logistical issues.

3. Key

Business Terms

●

Traceability: Ability to track the

origin and journey of Food products from farm to consumer.

●

Spoilage Risk: The probability of Food

becoming unsuitable for consumption due to poor storage, transport, or

environmental factors.

●

Predictive Analytics: Use of data and

machine learning models to forecast potential risks and optimize processes.

●

Clustering and Classification: Grouping

and categorizing supply chain entities to better understand patterns, quality

levels, and risk factors.

●

Recommendation System: An algorithm that

suggests optimal practices, routes, and partners in the supply chain based on

past data and performance.

4. Design

& Architecture

4.1 System Architecture

The platform architecture includes

three main layers: Data Processing, Graph Database, and Machine Learning Models.

●

Data Processing Layer: Ingests data from

sensors, transactional records, and historical data. Uses Apache Spark for data

cleaning, preprocessing, and streaming.

●

Graph Database Layer: Neo4j manages the

Food supply chain as a graph structure, with nodes for different entities

(e.g., Farm, Processing Plant, Distributor) and edges representing

relationships (e.g., SUPPLIES, DELIVERS).

●

ML Model Layer: Various ML models for

prediction, classification, clustering, and recommendation are trained and used

to identify potential risks and optimize decision-making.

4.2 Data Flow and Integration

- Data Ingestion: Collect data from various sources (farms, distribution

centers, IoT sensors).

- Data Transformation:

Use Spark to preprocess, clean, and transform the data.

- Storage in Neo4j:

Load structured data into Neo4j as nodes and relationships.

- ML Model Deployment: Train ML models on historical and streaming data. Store model

outputs (e.g., risk predictions) in Neo4j and periodically update based on

incoming data.

5.

Technologies

●

Apache Spark: For batch and real-time

data processing.

●

Neo4j: For managing supply chain data in

a graph structure.

●

Python: Language for developing and

deploying ML models and data processing scripts.

●

TensorFlow or PyTorch: For building deep

learning models, especially for time series forecasting and classification.

●

Scikit-Learn: For simpler ML models

(e.g., clustering, decision trees).

●

Kafka: For handling real-time data

ingestion if streaming is required.

●

Docker: For containerizing the

platform’s various components for easier deployment and scaling.

6.

Implementation

6.1 Data Collection

●

Define data sources for data

collection from farms, IoT devices, distribution points, and retail outlets.

6.2 Data Preprocessing

●

Use Apache Spark to clean and

transform raw data into a structured format suitable for Neo4j and ML models.

●

Create Spark jobs for batch and

real-time processing.

6.3 Graph Database Design

●

Define Neo4j nodes and

relationships based on the supply chain entities (e.g., Farm, Processing Plant,

Distributor, Retailer).

Graph Database

Design

The updated design will focus on the

traceability of onions rather than eggs:

- Define Neo4j Nodes

and Relationships Based on Supply Chain Entities

○

Nodes:

■

Farm

■

Attributes: farm_id, location, type

(e.g., organic, conventional), owner, certification_details

■

Manufacturer

■

Attributes: manufacturer_id, name, facility_location, processing_capacity, certifications

■

Processing Plant

■

Attributes: plant_id, name, location, handling_capacity, processing_methods

■

Distributor

■

Attributes: distributor_id, name, distribution_centers, coverage_area

■

Retailer

■

Attributes: retailer_id, name, location, store_type (e.g., supermarket), storage_conditions

■

Consumer

■

Attributes: consumer_id, location, purchase_date, feedback

■

Logistics Provider

■

Attributes: provider_id, name, fleet_size, transport_type (e.g., refrigerated), track_and_trace_capability

■

Warehouse

■

Attributes: warehouse_id, name, location, storage_capacity

○

Relationships:

■

(Farm) -[SUPPLIES]-> (Manufacturer)

■

Represents the supply of raw

onions from farms to manufacturers.

■

(Manufacturer) -[PROCESSES]-> (Processing Plant)

■

Represents the processing of

onions for packaging and distribution.

■

(Processing Plant) -[PACKAGES_FOR]-> (Distributor)

■

Represents the packaging of

onions specifically for distributors.

■

(Distributor) -[STORES_IN]-> (Warehouse)

■

Represents the storage of

onions by distributors in warehouses for further distribution.

■

(Warehouse) -[SHIPS_VIA]-> (Logistics Provider)

■

Represents the role of

logistics providers in transporting onions from warehouses to retailers.

■

(Logistics Provider) -[DELIVERS_TO]-> (Retailer)

■

Represents the delivery of

onions to retailers.

■

(Retailer) -[SELLS_TO]-> (Consumer)

■

Represents the sale of onions

to end consumers.

■

(Logistics Provider) -[MONITORED_BY]-> (IoT Sensor)

■

Represents the integration of

IoT sensors to monitor transportation conditions (e.g., temperature, humidity)

for onions.

6.4 Machine

Learning Models

Predictive

Analytics Models

These models help predict potential

risks in the supply chain, such as spoilage or transportation delays.

●

Time Series Forecasting Models:

○

ARIMA, SARIMA: Useful for predicting

temperature, humidity, or demand based on historical data. These models can

forecast conditions that may affect the quality of onions, such as fluctuations

in warehouse temperatures or seasonal demand changes.

○

LSTM (Long Short-Term Memory) Networks:

A type of recurrent neural network (RNN) that captures long-term dependencies

in time-series data. It can help predict conditions impacting onion quality,

such as trends in storage temperature or transportation delays.

○

Prophet: Suitable for seasonality and

trend forecasting, which can predict potential disruptions in the availability

or demand for onions.

Anomaly

Detection Models

These models identify abnormal

conditions that could indicate risks to the quality and safety of onions.Using biosensors

we can detect harmful bacteria at different stages in the supply chain (e.g.,

at farms, processing plants, or retail outlets).

●

Isolation Forest: Detects outliers by

isolating each point in the dataset. It is useful for spotting unusual

environmental conditions, such as unexpected temperature spikes during storage

or transportation.

●

One-Class SVM (Support Vector Machine):

Classifies data as either normal or anomalous. This model can identify unusual

sensor readings that may indicate a risk to onion quality, such as excessive

humidity.

●

Autoencoders: Neural networks that

detect anomalies in high-dimensional data, making them suitable for identifying

abnormal patterns across multiple sensors monitoring onion batches.

Risk

Prediction using Classification Models

These models predict the likelihood of

spoilage or other quality-related risks.

Biosensors for Real-Time Monitoring: Use biosensors

dataset to monitor environmental conditions like humidity, temperature, and

microbial contamination in storage facilities. These sensors can send real-time

data to the traceability platform, improving the system's ability to detect

risks.

Bioremediation Solutions: Using microorganisms to clean

up any contaminants in the environment (e.g., soil or water) where onions are

grown, thus reducing the initial risk of contamination.

Development of advanced molecular techniques, such as PCR

(Polymerase Chain Reaction) and CRISPR-based diagnostics, for quickly detecting

pathogens like E. coli in onions. These methods can be integrated with the

traceability platform to flag contaminated batches in real time.

●

Logistic Regression: A simple and

interpretable model suitable for binary risk predictions, such as predicting

whether an onion batch is at risk of spoilage (yes/no).

●

Random Forest, Gradient Boosting (e.g., XGBoost): Tree-based ensemble models that classify risk levels (e.g., low,

medium, high) based on factors such as transportation conditions, storage

durations, and temperature control.

●

CatBoost: Handles categorical data

effectively without extensive preprocessing, ideal for mixed data types like

batch ID, supplier location, and transport method.

●

Use

biological data, such as microbial profiles, that can be integrated with

the machine learning models for predictive analytics. This can improve the

accuracy of models in predicting spoilage, contamination risks, and other

quality issues.

Classification

Models

These models help sort batches,

identify quality grades, or flag defective products.

●

Support Vector Machine (SVM): Effective

for binary or multi-class classification, such as categorizing onions based on

quality grades (e.g., Grade A, B).

●

Decision Trees and Random Forests:

Suitable for hierarchical classification of onion batches based on attributes

like size, weight, and quality. These models provide interpretability for

identifying specific factors affecting quality issues.

●

Convolutional Neural Networks (CNNs):

Useful for image classification during visual inspections, such as detecting

signs of rot, mold, or other defects in onions. A CNN can analyze images

captured during sorting and flag defective onions.

●

Naive Bayes: Can classify onions based

on categorical attributes (e.g., organic, conventional). It's fast and performs

well when features are independent, which is often the case with product

attributes.

Clustering

Models

Clustering helps group similar

batches, identify quality patterns, or segment distributors based on

performance.

●

K-Means Clustering: Groups onions,

farms, or batches based on similar characteristics (e.g., freshness, size,

location). Useful for segmenting suppliers and identifying quality patterns

among batches.

●

DBSCAN (Density-Based Spatial Clustering of Applications with

Noise): Finds clusters of arbitrary shapes, making

it ideal for segmenting onion suppliers or distributors by geographical

regions. It can help detect regional quality issues or high-risk zones.

●

Hierarchical Clustering: Allows a

hierarchical structure in clustering, which can categorize farms based on

multiple factors like region, size, and compliance history.

●

Gaussian Mixture Models (GMM): A

probabilistic clustering model suitable for grouping batches with mixed

distributions, such as varying freshness levels in different regions or under

different storage conditions.

Recommendation

Models

Recommendation models support supply

chain decision-making by suggesting optimal routes, suppliers, or practices

based on historical data and performance.

●

Collaborative Filtering (Matrix Factorization, SVD): Provides recommendations based on patterns in historical data. For

example, it can suggest preferred logistic providers or routes to minimize

spoilage during onion transport.

●

Content-Based Filtering: Recommends

suppliers or distributors based on attributes such as certification, proximity,

and transport reliability. This model helps in selecting suppliers that meet

quality and freshness requirements.

●

Association Rule Learning (e.g., Apriori, FP-Growth): Analyzes patterns among different conditions (e.g., temperature

ranges or transport durations that correlate with better quality retention). It

is useful for optimizing storage conditions or identifying risky combinations

of transport and storage conditions.

●

Deep Neural Networks (DNNs): Can be used

for complex recommendation systems that factor in dynamic elements like

real-time sensor data and historical quality incidents. DNNs provide more

adaptive and granular recommendations for supply chain decisions.

5. Supply

Chain Optimization Models

These models help optimize supply

chain processes by predicting delays, managing inventory, and minimizing waste,

which is crucial for perishable items like onions.

DNA

Fingerprinting and Whole Genome Sequencing (WGS):

genomic tracing to identify the genetic signature of pathogens. WGS can help

trace the contamination back to specific batches or even the original farm

source.

Strain

Typing: Techniques can differentiate between strains of pathogens

to establish whether cases of E. coli are linked to the same source, aiding the

investigation and narrowing down the origin of contamination.

CRISPR-Based

Gene Editing: Gene editing techniques can be used to

create onion varieties that are more resilient to environmental stressors like

drought or temperature changes, ensuring better storage and longer shelf life,

thus reducing spoilage risk

Microbiome

Analysis: By analyzing the microbiome of onion batches at

different stages, biotechnology can help identify microbial patterns associated

with spoilage or contamination, enabling early intervention

Optimization Algorithms

●

Linear Programming (LP):

○

LP can be used to minimize

costs or maximize efficiency in various supply chain decisions. For onions, LP

can optimize the routing of shipments to minimize transportation costs while

considering constraints like delivery deadlines, temperature control, and

storage capacity.

○

An objective function might be

formulated to minimize the total cost of transportation, considering factors

such as distance, delivery time, and refrigeration needs, subject to

constraints like vehicle capacity and warehouse limits.

●

Genetic Algorithms (GA):

○

GA can optimize complex

problems in the supply chain, such as route planning for delivering onions to

multiple retailers while considering varying delivery windows and traffic

patterns.

○

It can also be used to find the

optimal combination of suppliers that balance cost, quality, and reliability,

helping to ensure a consistent supply of high-quality onions while minimizing

costs.

Inventory Management Models

●

Economic Order Quantity (EOQ):

○

EOQ helps determine the optimal

order quantity that minimizes total inventory costs, including ordering and

holding costs. For onions, EOQ can be adjusted based on factors like shelf

life, storage conditions (e.g., temperature and humidity), and demand variability.

○

The EOQ formula is given by:

EOQ=2DSHEOQ = \sqrt{\frac{2DS}{H}}EOQ=H2DS where DDD is the annual demand for

onions, SSS is the ordering cost per order, and HHH is the holding cost per

unit per year.

●

Reorder Point (ROP):

○

ROP models determine the

inventory level at which a new order should be placed to avoid stockouts. For

onions, this model accounts for the lead time, demand during the lead time, and

safety stock to handle unexpected demand fluctuations or delivery delays.

○

The ROP formula can be given

by: ROP=(Lead Time Demand)+Safety StockROP = (Lead \, Time \, Demand) + Safety

\, StockROP=(LeadTimeDemand)+SafetyStock

○

For onions, factors like

spoilage rates and seasonal demand spikes would influence safety stock

calculations.

Vehicle Routing Problem (VRP) Solutions

●

Ant Colony Optimization (ACO):

○

ACO can solve VRP scenarios

where multiple delivery vehicles need to be routed efficiently. This approach

is suitable for distributing onions from warehouses to retail locations,

considering constraints such as vehicle capacity and delivery time windows.

○

The algorithm uses a

probabilistic technique inspired by the behavior of ants searching for food,

which helps identify optimal paths for delivery routes to minimize total travel

time or distance while ensuring timely delivery of perishable goods like onions.

●

Simulated Annealing (SA):

○

SA can be used to optimize

delivery schedules for onions to multiple destinations. It starts with a random

solution and iteratively improves it by exploring neighboring solutions,

mimicking the process of annealing in metallurgy.

○

For onions, SA can help

optimize routes while considering variables like refrigeration availability and

traffic patterns, aiming to reduce spoilage and transportation costs.

Inventory Optimization using Time Series

Forecasting

●

Seasonal Stock Adjustment:

○

Models like ARIMA or Prophet can predict seasonal demand variations for onions, helping

adjust stock levels proactively. These models forecast demand spikes or dips

based on historical sales data, allowing for dynamic stock management.

○

Predictions can be integrated

with EOQ and ROP models to update inventory policies in real-time, reducing the

risk of spoilage during low-demand periods and ensuring sufficient stock during

high-demand seasons.

Waste Minimization Strategies

●

Perishable Goods Allocation Models:

○

Models like First-Expire, First-Out (FEFO) are

implemented to prioritize the distribution of onions nearing the end of their

shelf life. This approach reduces waste by ensuring older inventory is shipped

out before newer stock.

○

Predictive Analytics can identify which

batches of onions are more likely to spoil based on environmental conditions

and historical data. This information can be used to optimize stock rotation

practices.

●

Multi-Echelon Inventory Optimization:

○

This approach manages inventory

across different levels of the supply chain (e.g., warehouses, distribution

centers, retail outlets). Multi-echelon optimization can be used to balance

stock levels, ensuring that onions are available where needed while minimizing

total inventory costs.

○

Advanced techniques like Stochastic Inventory Models can account

for demand uncertainty and lead-time variability in multi-echelon networks.

These models enhance the efficiency of

onion supply chains by optimizing logistics, managing inventory effectively,

and minimizing waste, contributing to a more transparent and resilient food

traceability system.

6.5 Integration and Deployment

●

Integrate Neo4j and Spark to

allow seamless data flow between data processing and the graph database.

●

Containerize the application

components using Docker for scalability.

●

Deploy ML models and

periodically update predictions based on real-time data ingestion.

7. Testing

7.1 Unit Testing

●

Conduct unit tests on

individual components like data preprocessing, ML model functions, and Cypher

queries.

7.2 Integration Testing

●

Test end-to-end data flow from

ingestion, processing, storage in Neo4j, and prediction with ML models to

ensure all components work cohesively.

7.3 Performance Testing

●

Evaluate system performance to

ensure it can handle high data volumes, especially for real-time data ingestion

and querying in Neo4j.

7.4 Model Evaluation

●

Use metrics like accuracy,

F1-score, precision, and recall for classification models.

●

Evaluate clustering models

using silhouette scores and adjust the parameters accordingly.

●

Measure time series model

accuracy using metrics such as RMSE and MAPE.

8. Reports

8.1

Traceability Reports

●

Purpose: Provide a visual representation

of the entire supply chain journey of each batch of onions, from farm to

retailer, including details about every processing, storage, and transportation

step.

●

Content: Show the path taken by recalled

batches of yellow onions, highlighting entities involved (e.g., Taylor Farms,

distributors, restaurants like McDonald’s). The report will include timelines

and locations, enabling investigators to quickly identify where the onions may

have become contaminated.

●

Focus Area: The report will emphasize

the batches supplied to McDonald's and other affected food service customers,

showing all steps before the voluntary recall was issued.

8.2 Quality

Risk Analysis

●

Purpose: Assess the risk levels for

batches of onions based on factors such as spoilage predictions, environmental

conditions, and transport data.

●

Content: Include risk scores for the

batches involved in the recall, evaluating spoilage risk or contamination

likelihood based on conditions such as temperature and humidity during storage

and transportation.

●

Investigation Aid: Use risk scores to

prioritize the analysis of batches that may have higher contamination risks,

aiding in determining whether slivered onions supplied to McDonald’s were the

likely source of the E. coli outbreak.

8.3 Anomaly

Detection Report

●

Purpose: Identify any anomalies in

environmental conditions (e.g., temperature, humidity) throughout the onion

supply chain that could contribute to quality issues or contamination risks.

●

Content: Highlight unusual readings from

IoT sensors during the storage or transport of recalled onion batches. For

example, sudden temperature spikes in warehouses or during transportation could

indicate potential quality degradation.

●

Suggested Actions: Recommend actions to

address detected anomalies, such as increasing inspections or adjusting storage

conditions for other batches from the same supplier to prevent further

contamination.

8.4 Supplier

and Distributor Performance Reports

●

Purpose: Evaluate the performance of

suppliers and distributors based on key metrics like quality consistency,

delivery time, and customer feedback.

●

Content: Analyze performance data for

Taylor Farms and other distributors who handled the recalled onions,

identifying any patterns in quality issues. The report will assess compliance

with quality standards across different distribution centers.

●

Ranking: Rank suppliers and distributors

based on their performance history, allowing McDonald’s and other food service

customers to make informed decisions about sourcing onions in the future.

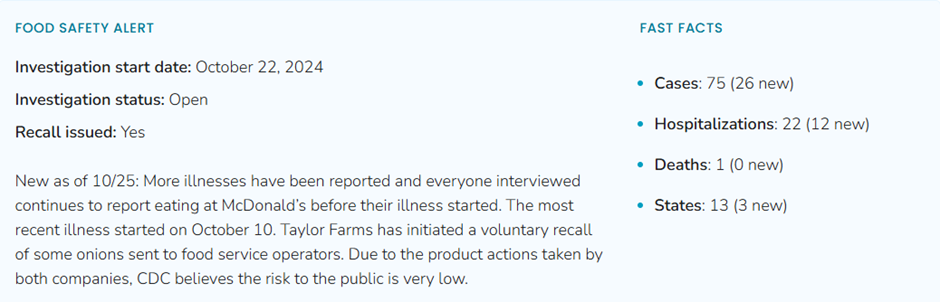

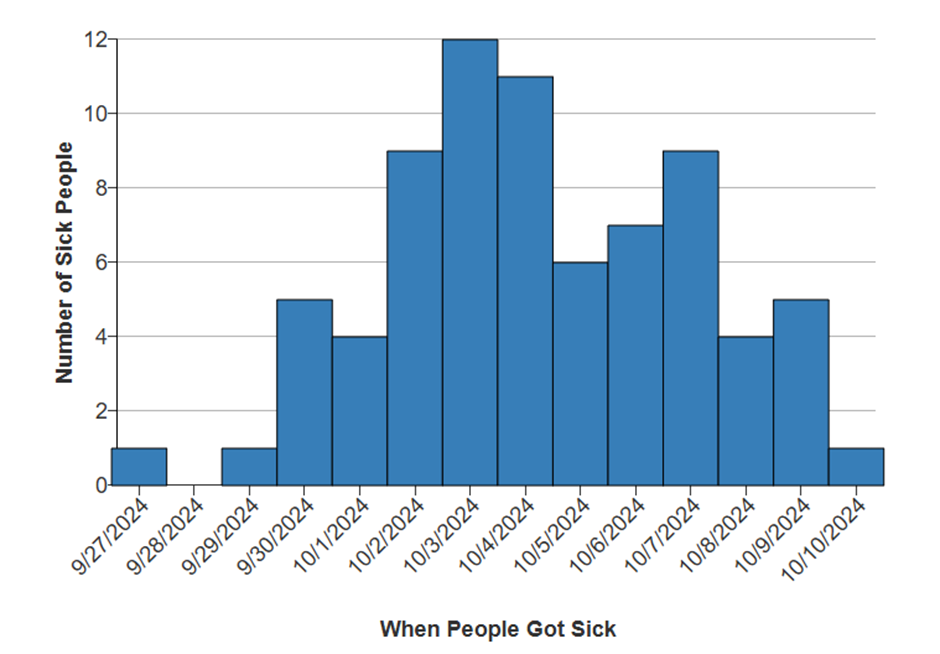

8.5 Outbreak

Status and Recall Impact Report

●

Purpose: Track the status of the ongoing

E. coli outbreak investigation and measure the impact of the recall.

●

Content: Provide an update on the number

of reported cases, hospitalization data, affected states, and the steps taken

by Taylor Farms and McDonald’s to address the situation. Include details about

the investigation's progress and any new findings related to the potential

source of contamination.

●

Recall Effectiveness: Evaluate the

effectiveness of the recall measures taken, including the removal of slivered

onions from McDonald's menus in affected states and notifications sent to other

food service customers.

8.6

Visualisations

References

https://www.youtube.com/watch?v=K-s4hr87994

https://www.youtube.com/watch?v=NqsGIjWjiCQ

No comments:

Post a Comment